OPC UA is Enabling Smart Manufacturing - Report from OPC Day Finland 2017

25.10.2017

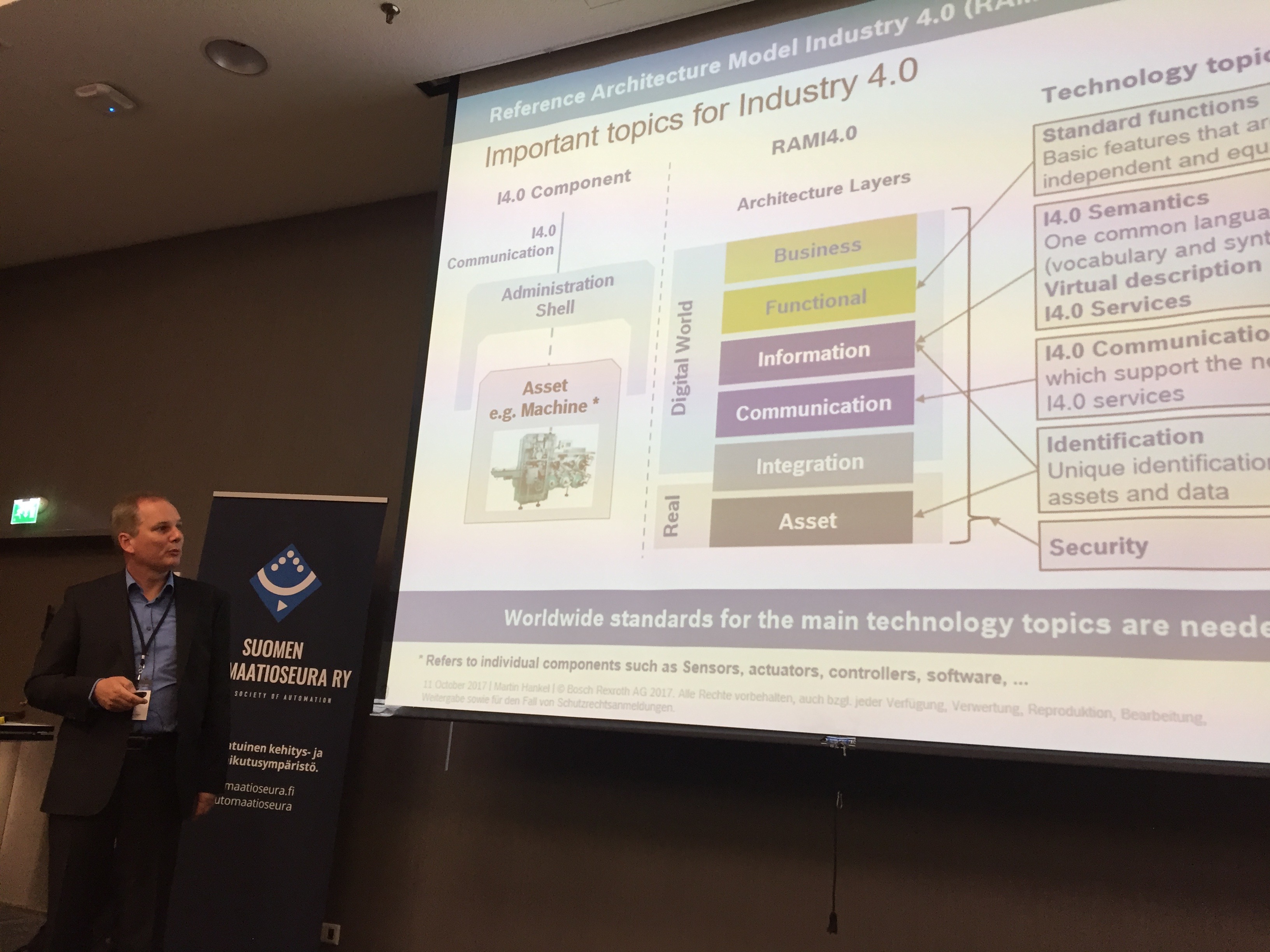

Manufacturing moves towards modular and cellular assembly lines and improved configuration options. Smart manufacturing concepts enable more flexible configuration of production lines and faster adaptation to new product orders. OPC UA is playing a key role in enabling Industrie 4.0 Communication and Information layers. Similar architecture models are being defined in different national and international consortiums around the world.

“Industry 4.0, Industrial Internet Consortium, Made in China 2025, etc. are adopting OPC UA as the Communication Protocol of Choice.” This was the main message from the OPC Day Finland 2017, which took place in context of the Teknologia ‘17 Trade Show in Helsinki.

A total of 70 enthusiasts joined the “Best OPC Day Finland ever” that we arranged together with the Finnish Society of Automation for the 13th time in as many years.

The keynote speakers, Martin Hankel (Bosch Rexroth & Plattform Industrie 4.0) and Jouni Aro (Prosys OPC & OPC Foundation), outlined how OPC UA is becoming a dominant standard for the communication and information layers of all major smart manufacturing architectures in the world.

Industrie 4.0 and other international activities

Martin Hankel is a leading character in the German Industrie 4.0 initiative that has been designing the Reference Architecture Model for Industrie 4.0 (RAMI 4.0). He is also an active member of several international Joint Working Groups that are negotiating the streamlining of various national architecture models to a common model. OPC UA has already been made a compulsory requirement for Industrie 4.0 Components and the same trend is seen in other architecture models.

OPC Foundation has been signing several collaboration agreements with different organizations around the world, including the Industrial Internet Consortium (IIC) in North America and Manufacturing Industry Innovation 3.0 in Korea. The Chinese national standardization committee TC124 has already adopted most of the OPC UA specifications to their standards.

OPC UA and real-time communication

Heinrich Munz from Kuka Group gave an enthusiastic speech about Time Sensitive Networks (TSN) and OPC UA. TSN is the real-time enhancement to the standard Ethernet IEEE802.1 communications currently under development. Industrial manufacturers are currently struggling with the multitude of different fieldbus protocols not compatible with each other. TSN and standard Ethernet based communication would solve that compatibility issue. At the time OPC UA will be able to leverage the technology, the industrial integration of systems from various vendors will be greatly simplified.

Munz also emphasized the importance of Client/Server communication for cloud networks, which has been largely ignored in the recent marketing of the new Publisher/Subscriber model. The new model is providing means to deliver data to cloud systems in connectionless ways. However, the downside of the Publisher/Subscriber model is that it is one directional. In practice, we will not be able to give up the important functionality provided by the current OPC UA Client/Server technology: browsing the information models, calling methods and subscribing to data and events from the servers directly. All this is required for cloud applications as well, and OPC Foundation is actually defining AMQP based Client/Server transport protocol for the upcoming 1.04 version of the OPC UA specification to target this.

Labs Network Industrie 4.0 (represented by Dominik Rohrmus) is helping the German industry to accomplish the standardization challenges of Industrie 4.0 by pre-checking and validating the proposed architecture and products in practice. The network is comprised of 30 independent laboratories working together to provide a wide scope of expertise for different technologies. The TSN testbed is also installed in a truck, which can go wherever necessary, including trade shows, conferences and training. It is a very flexible concept and can help the industry to validate the TSN implementations from controller to controller robotic solutions to MES systems. LNI is well connected also internationally and will have co-operation with OPC Foundation as well.

Cellular assembly lines

SAP’s agent based manufacturing execution relies on every component in the production line (robots, grippers, transport systems, etc.) having a built-in OPC UA client and server. Rüdiger Fritz also mentioned the new paradigm of modular assembly lines where products are assembled in reconfigurable cells. This will enable a new level of flexibility to the production lines, allowing highly customizable products. Each product can take a different path in the production depending on the individual requirements of each customer.

Real-world case studies

Jukka Asikainen (Prosys OPC) showcased the Krüger case, where OPC UA was used to build a highly flexible cloud based solution to managing an increasing number of waste water treatment plants. The solution is based on Docker servers running in Amazon Web Services. This solves several issues in relation to load balancing and dynamic allocation of resources as new production sites are added to the centrally managed system.

Andreas Frejborg (Neste Jacobs) presented the highly successful Neste Advanced Process Control (NAPCON) Suite, which is built on top of OPC Unified Architecture and is now Certified for Compliance by the OPC Foundation. The product has created a huge new business, ranging from petrochemical to biopharma and food industry, to Neste Jacobs, the company behind the product.

Mika Karaila (Valmet) presented the Robot Framework and how it has helped testing the upcoming OPC UA server implementation of Valmet DNA. We also heard from interesting real-world cases made with Kepware, Beckhoff and Bosch Rexroth OPC UA products.

Check out the online recordings or get the event material from the event home page to learn more about the topics.

Check the Case Studies for more about the Krüger and other Prosys OPC cases.

Jouni Aro

Chief Technology Officer

Email: jouni.aro@prosysopc.com

Expertise and responsibility areas: OPC & OPC UA product development, project work and customer support

Tags: Events, OPC UA, IoT, OPC Day

comments powered by DisqusAbout Prosys OPC Ltd

Prosys OPC is a leading provider of professional OPC software and services with over 20 years of experience in the field. OPC and OPC UA (Unified Architecture) are communications standards used especially by industrial and high-tech companies.

Newest blog posts

Why Do Standards Matter in Smart Manufacturing?

The blog post discusses the importance of standards in smart manufacturing, envisioning a future where auto-configurable systems in manufacturing rely on standardized data formats for seamless integration and reduced costs, with a focus on the OPC UA standard family as a key enabler.

OPC UA PubSub to Cloud via MQTT

Detailed overview of the demo presented at the OPC Foundation booth

SimServer How To #3: Simulate data changes on a server using an OPC UA client

A two-part step-by-step tutorial on how to write data changes on an OPC UA server using an OPC UA client.